Hardox steel is known for its exceptional hardness, toughness and abrasion resistance – and the Hardox 400 plate is no exception. This all-round, wear-resistant steel has a nominal hardness of 400 HBW, with a toughness, bendability and weldability that makes it suitable for structures and components subject to moderate wear.

Mechanical characteristics of HARDOX400 wear plate:

(Typical parameters of 20mm thick steel plate) 1MPa=1N/m㎡

Equivalent CET (℅) [CET=C+( Mn+Mo)/10+(Cr+Cu)/20+Ni/40]: 0.35

Carbon equivalent CEV (℅) [CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15]: 0.53

| Yield Strength(MPa) |

tensile strength(MPa) |

ElongationA5(℅) |

Impact test(-40℃) |

| 1000 |

1250 |

10 |

45 |

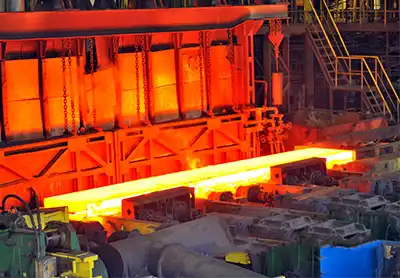

Delivery status:

The delivery status is quenched. Open slab without primer, for cutting or thermal cutting edge. The surface of the medium and heavy plate is pretreated with red anti-rust paint, and the edges are cut or hot cut. Hardness range 370-430 (HBW).

HARDOX400 wear-resistant steel plate heat treatment:

Hardox 400 obtains its mechanical properties by means of quenching (if necessary, tempering continues after quenching). However, after the steel plate is used or the preheating temperature exceeds 250°C, the performance will not be guaranteed to be the same as the performance specified in the delivery conditions. Hardox 400 does not require any further heat treatment.

HARDOX400 wear-resistant steel plate thermal processing:

In the process of welding, cutting, grinding, and other processing steel plates, appropriate precautions to protect health and safety need to be taken. Especially when sanding, due to the anti-rust paint on the surface of the steel plate, dust with high concentration of fine particles may be generated. If necessary, we will provide more detailed related information.